PBT (Polybutylene terephthalate)

PBT : Polybutylene terephthalate

CAS NO.: 26062-94-2

Capacity: 240kt/year

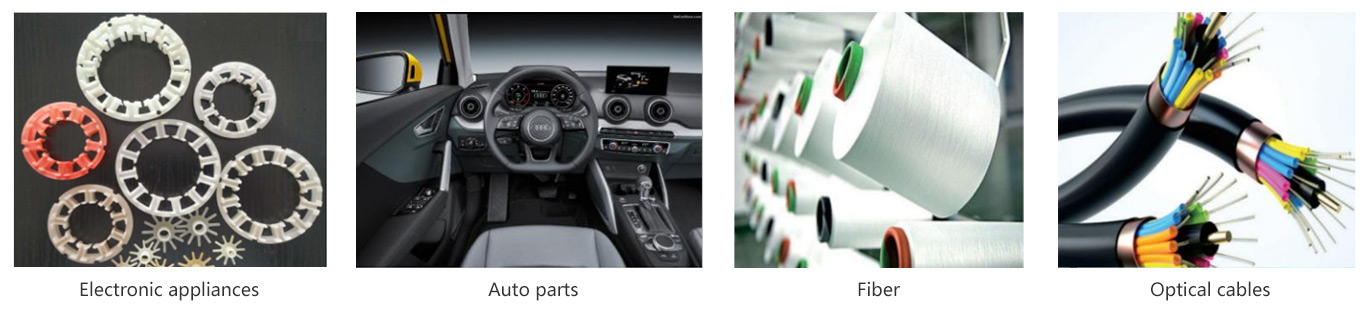

PBT is a high-performance thermoplastic engineering plastic made from PTA and BDO by a condensation reaction. It has excellent comprehensive performance and is widely used in industrial and consumer fields. PBT has become a key material for high-end manufacturing such as electronics and automobiles due to its heat resistance, chemical resistance, and easy processing. Through modification, the application scenarios can be further expanded to meet the industrial trend of lightweight and high performance.

Specification

PBT SPECIFICATIONS | |||||||||||

ITEM | UNIT | Method | TUNHE GRADE NO. | ||||||||

TH6068 | TH6075 | TH6080 | TH6082 | TH6085 | TH6090 | TH6095 | TH6100 | TH6100F | |||

Intrinsic Viscosity | DI/g | GBT/14190 | 0.680±0.012 | 0.750±0.012 | 0.800±0.012 | 0.820±0.012 | 0.850±0.012 | 0.900±0.012 | 0.950±0.012 | 1.000±0.012 | 1.015±0.012 |

Melting Point | ℃ | GBT/19466.3 | ≥222 | ≥222 | ≥222 | ≥222 | ≥222 | ≥222 | ≥222 | ≥222 | ≥222 |

Carboxyl End Groups | mol/t | GBT/14190 | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 | 18±2 |

Color(L) | - | GBT/14190 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 |

Color(B) | - | GBT/14190 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

Water Content | % | GBT/14190 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 |

Ash Content | mg/kg | GB/T9345.1 | ≤300 | ≤300 | ≤300 | ≤300 | ≤300 | ≤300 | ≤300 | ≤300 | ≤300 |

Weight of 100 Granule | g | GB/T 8170 | 2.2±0.2 | 2.2±0.2 | 2.2±0.2 | 2.2±0.2 | 2.2±0.2 | 2.2±0.2 | 2.2±0.2 | 2.2±0.2 | 2.2±0.2 |

Tensile strength | MPa | GB/T 1040.2 | / | / | / | ≥50 | ≥50 | ≥50 | ≥50 | ≥50 | ≥50 |

Bending strength | MPa | GB/T9341 | / | / | / | ≥60 | ≥60 | ≥60 | ≥60 | ≥60 | ≥60 |

Flexural modulus | MPa | GB/T9341 | / | / | / | ≥2000 | ≥2000 | ≥2000 | ≥2000 | ≥2000 | ≥2000 |

Impact strength of cantilever beam gap | J/M | GB/T1843 | / | / | / | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 |

Note: Customization and tailor made PBT is available upon customer requirements.

PBT SPECIFICATIONS | ||||||||

ITEM | UNIT | Method | TUNHE GRADE NO. | |||||

TH6110 | TH6120 | TH6090G | TH6100G | TH6120G | TH6125G | |||

Intrinsic Viscosity | DI/g | GBT/14190 | 1.100±0.012 | 1.200±0.012 | 0.930±0.020 | 1.000±0.020 | 1.230±0.020 | 1.250±0.020 |

Melting Point | ℃ | GBT/19466.3 | ≥222 | ≥222 | ≥222 | ≥222 | ≥222 | ≥222 |

Carboxyl End Groups | mol/t | GBT/14190 | ≤20 | ≤30 | ≤10 | ≤10 | ≤12 | ≤12 |

Color(L) | - | GBT/14190 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 |

Color(B) | - | GBT/14190 | ≤3 | ≤3 | ≤3 | ≤3 | ≤4 | ≤4 |

Water Content | % | GBT/14190 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 |

Ash Content | mg/kg | GB/T9345.1 | ≤300 | ≤300 | ≤300 | ≤300 | ≤300 | ≤300 |

Weight of 100 Granule | g | GB/T 8170 | 2.2±0.2 | 2.2±0.2 | 2.2±0.2 | 2.2±0.2 | 2.2±0.2 | 2.2±0.2 |

Tensile strength | MPa | GB/T 1040.2 | / | / | / | ≥50 | ≥50 | ≥50 |

Bending strength | MPa | GB/T9341 | / | / | / | ≥60 | ≥60 | ≥60 |

Flexural modulus | MPa | GB/T9341 | / | / | / | ≥2000 | ≥2000 | ≥2000 |

Impact strength of cantilever beam gap | J/M | GB/T1843 | / | / | / | ≥40 | ≥40 | ≥40 |

Product Application

Certificates and Compliance

EU-REACH / FDA food contact / EU food contact / ROHS / SVHC / SDS / KKDIK